?WHY CONTAINER SYSTEM

As you know, there are two general methods for the sterilization and protection of surgical instruments: single-use wrap and reusable sterilization container systems. The main differences between these methods are efficiency and return on investment.

:Return on Investment

The single-use wraps seem more economical at first view. They are single-use and disposable. However these medical wastes are 5-10% of the total medical waste streams of hospitals. Furthermore, single-use wraps can tear during the sterilization process because of any reason. In this case, sterilization is performed again and this may cause many delays. The aluminum sterilization containers can be considered as non-economic at first view but the lifetime of them is more than 5 years. When the lifetime is based on, the total cost reduces approximately at a rate of 70-80% more when compared with the cost of single-use wraps and that’s why they are more economical choice.

:Environmental Awareness

The containers has a big role for the care that we need to take for our life space which is polluted more day by day. The containers do not cause any kind of medical waste streams and protect the environment.

:Efficiency

Containerization is the most effective method of sterilization since you do not face any tearing. In terms of following and detecting the sterilization period and result, It increases the efficiency with accessories like automatic lock, indicator window and security seal.

:Reliability

They protects the surgical instruments in the maximum level with the help of their hard and sheltered structure.

:Ease of Identification

Reaching the information of instruments inside the container is easier due to the face plate that containers have in both sides. Moreover they provide ease of identification with the help of different lid color options creating color coding.

:Safe Handling

They enable more proper, easier and safer transportation with their ergonomic design and handles.

Beyond Sterilization

Box Types

Perforated and

Non-Perforated Container Options

Box Non Perforated

Box Perforated

Box Dimensions

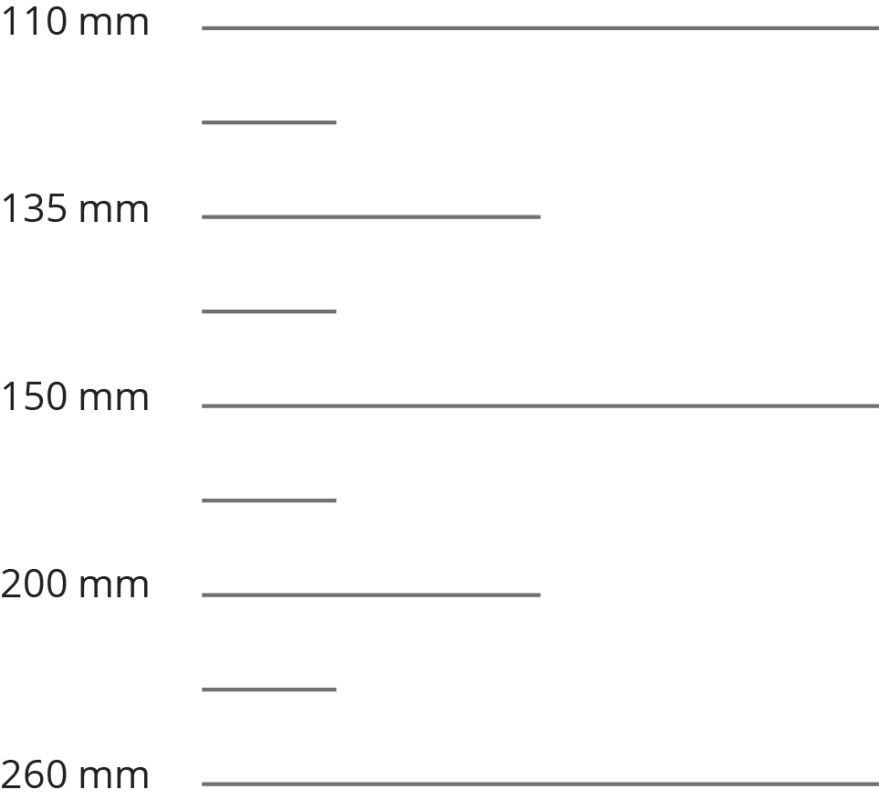

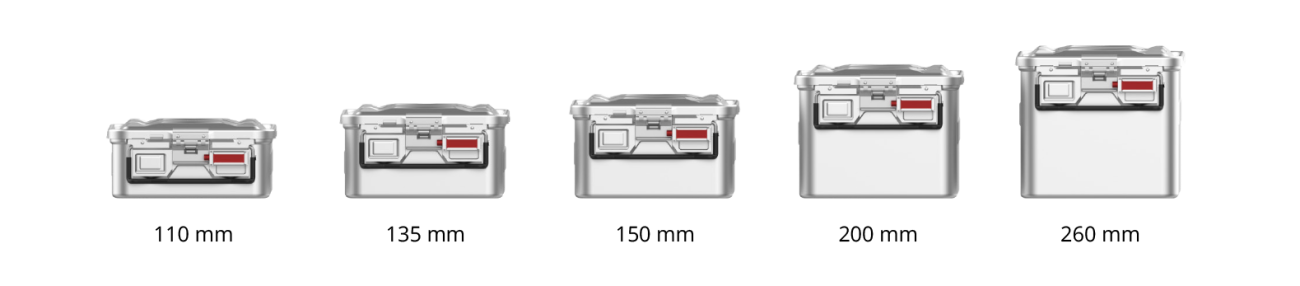

5 Different Dimensions

Aygün sterilization container systems, with most general point of view, are separated into 5 different dimension groups as 1/2, 3/4, 1/1, Extra Large and Extra Long models. Additionally, we can supply smaller models like Dental and Mini Sterilization Containers.

Standard

Dimensions